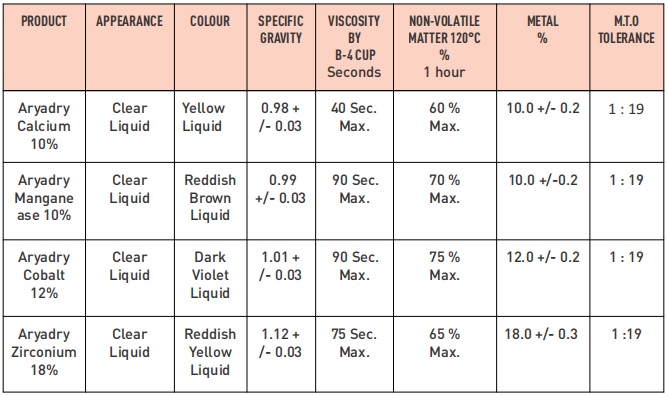

Aryavart Chemicals Pvt. Ltd. offers a complete range of Paint Driers developed specially for use as Driers in Paints and Varnishes. These are metallic salts of synthetic carboxylic acid, and are characterised by controlled metal concentration, compatability with the paint media and are subject to rigid quality control tests. Salts of napthenic acid used as driers have excellent solubility and stability and they are offered as solutions in mineral turpentine at definite metal concentrations. Octoates/ Iso Octoates are metallic salt solutions of synthetic carboxylic acid which have a definite composition and are of the lightest colour. They compare in drying performance to naphthenates but have a lighter colour, lower viscosity and less odour and have a precise composition. To manufacture these products we have set up a hi-tech plant to manufacture 12000 MT per annum of Paint Driers at Jalgaon. International trade magazines have taken note of this plant.